Machines and the office are powered by green electricity

In 2018 Houweling Group laid down one of the largest photovoltaic roofs in South Holland. With it, we generate 3.7 MWp of solar energy. This is sufficient energy to supply the machines and the office with green electricity. We have thus realised the sustainable ambition to work in an energy-neutral office.

Read the article

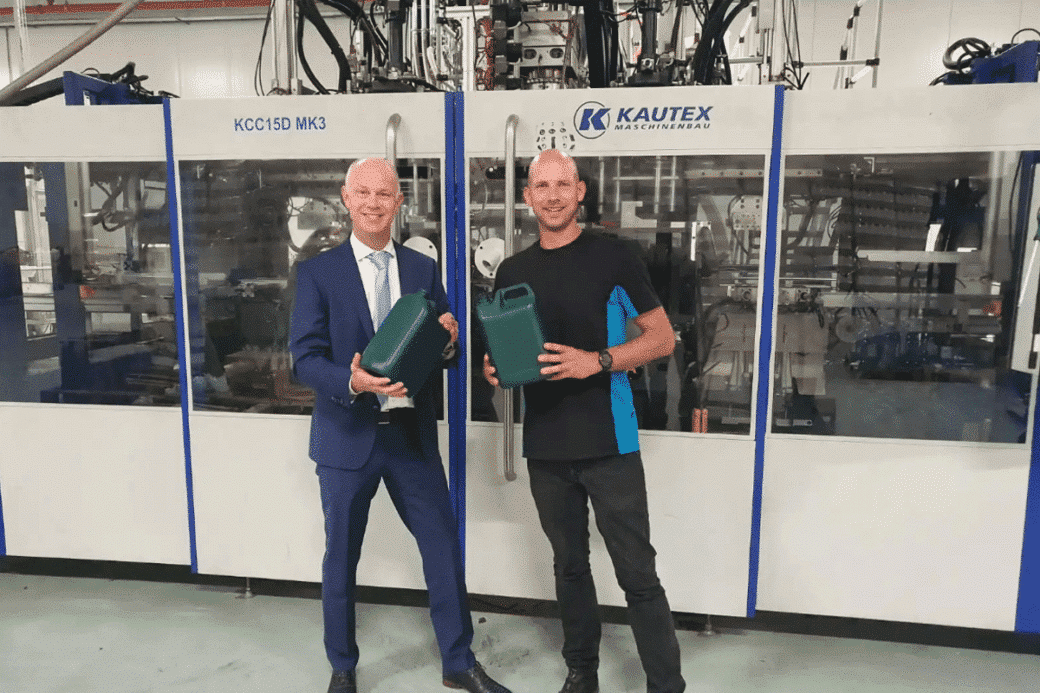

100% recycled plastic

Waste is raw material. We collect used materials for reuse. We have a shredder on site to recycle used materials. We are the only company to produce our own jerrycans and watering cans from 100% recycled plastic.

The machines are electric and run on green electricity generated by our own solar panels. In 2022 we produced over 1 million items from PCR materials.

Ask a question about recycled plastic.

Reconditioning packaging

The reconditioning of used IBCs leads to a

CO2 reduction of 95% compared to the production of new IBCs on a steel pallet. The lifespan of a used IBC is thus extended by 2.5 years on average. By rinsing with filtered rainwater, we also save 120L/IBC of drinking water.

We also recondition HDPE containers. This leads to a CO2 reduction of 86.5% compared to a 100% new container. Because we also use rainwater in this process, we save 100L/container of drinking water. Two other sizes of jerrycans (20 and 25L) are reconditioned by us.

Read more about recoservice

Drinking water savings

In the reconditioning process of IBCs, i.e. the cleaning of used IBC containers so they can be used again for packaging, a lot of water is used. We have been able to replace half of this amount with rainwater collected from our warehouse in Belgium and used for rinsing. This has led to savings of 5 million litres of drinking water.

In addition, the water used for rinsing is not discharged but collected and processed into fish feed.

Sharing is the new way to multiply!

At the start of each year, Houweling Group searches for three projects that it wants to support. This year it contributed to Kika and Stichting Jarige Job. There is also a goal that the Houweling Group has been actively supporting for decades: fighting poverty in Romania through Stichting Sarfath and Zending over Grenzen. The fact that Houweling Group has its own transport service has been very useful in this support.

Read the interview with Bert-Jan Houweling about:

The special connection to Romania

EcoVadis certification

Houweling Group scored among the best 25% of companies in the world in the field of sustainability and corporate social responsibility.

Houweling Group was awarded a silver sustainability certificate from EcoVadis in the 2022 assessment for CSR. EcoVadis is an independent organisation that assesses the policy of companies in terms of CSR. The EcoVadis label is recognised in over 160 countries, and each year companies in almost 200 different sectors are evaluated.

.

Read the article

Innovation in plastic

In 2022 the Houweling Group succeeded in producing a complete jerrycan from plastic obtained from the ocean. What a performance! This was the first blow moulding product in the world made from ocean waste.

In 2016 we were the first company to develop a series of bottles made entirely from recycled plastic. The bottles consisted of 100% post-consumer recycled HDPE and led to CO2 savings of 75% compared to virgin material and a savings of 95% on fossil fuel raw materials.

We were the first company in the world with this form of ‘plastic waste transformed into new packaging’.

Read the article